Key takeaways

- The Netherlands must build over 900,000 new homes by 2030, but regulatory and environmental complexities are slowing progress.

- UBQ™ offers a ready-to-use, climate-positive material made from waste that supports sustainable building at scale.

- Compatible with standard polymers, UBQ™ integrates into existing processes and is already used in products like flooring, cladding, and piping.

- UBQ™ helps address the environmental impact of housing construction, aligning with circular economy goals and stricter ecological standards.

According to government estimates, over 900,000 new homes must be built by 2030 to meet demand across Dutch cities and regions. Yet construction is falling behind.

Several intersecting regulatory and environmental challenges are also contributing significantly to the housing shortage.

Housing Projects Delayed by Nitrogen Rules

The 2019 court ruling on nitrogen emissions set off a chain of consequences for the Dutch housing market. Permitting now requires proof that new construction projects will not increase nitrogen emissions, especially near sensitive Natura 2000 conservation areas. This “internal netting” mechanism once allowed developers to rely on previously permitted emissions to move forward with new building activity at the same location.

However, in December 2024 the Council of State “ruled that internal balancing has been found to require a permit (almost always). This applies retroactively,” fundamentally changing what developers can rely on when applying for a nature permit. In practice, this means that past nitrogen rights can no longer be counted in advance and even previously permitted projects are suddenly in violation until they obtain a new nature permit.

As experts warn, this ruling imposes “a very large impact on all situations in which internal netting is possible or necessary”, contributing to severe uncertainty in the planning pipeline. As a result, nearly 244,000 housing units, almost one-third of the national target, are at risk of delay or cancellation due to permitting paralysis under the Council of State decision.

Further compounding this pressure, a news report highlighted that plans for up to 500,000 additional homes could stall in the coming years due to the combined effect of the nitrogen impasse and constraints on the electricity grid. Under regional housing agreements, provinces and municipalities have committed to delivering nearly one million more houses by 2030. Yet while around 260,000 homes were completed in the first three years, annual output dropped to 84,000 last year, falling short of the planned acceleration toward 100,000 per year.

Together, these findings signal that without targeted national intervention and scalable solutions that fit within nitrogen and grid limitations, the Netherlands risks falling significantly behind its 2030 housing objectives.

New Rules Under the Omgevingswet

The Omgevingswet, which took effect in 2024,consolidates existing Dutch environmental laws under stricter sustainability criteria, in line with broader EU frameworks such as the Circular Economy Action Plan and the Fit for 55 targets. Developers must now consider soil quality, zoning, and multiple environmental impacts like air quality, noise, and biodiversity in permit applications. While designed to streamline and modernize environmental governance, the reform has added new layers of complexity and uncertainty for housing construction.

In the face of tightening regulations, the challenge for Dutch housing developers is no longer just about building homes, it’s about building homes that meet radically higher environmental standards. That’s where UBQ™ becomes relevant.

Why This Matters to UBQ

The Netherlands housing crisis is not just a story of housing shortage, it’s a crisis of compliance, cost, and complexity. With more than 900,000 homes needed by 2030, the country’s ability to build is being stopped by environmental limits. For developers, this raises a difficult question: how do you deliver affordable housing at scale without triggering nitrogen violations or exceeding carbon targets?

Traditional Materials Are Blocking Progress

The vast majority of housing projects today still rely on high-impact materials like cement, steel, and fossil-based plastics. This dependence comes at a high cost:

- The building and construction sector consumes 32% of global energy and accounts for 34% of global CO₂ emissions.

- Materials like cement and steel alone are responsible for 18% of global emissions and generate substantial construction waste.

- These inputs release large amounts of carbon dioxide (CO₂) and nitrogen oxides (NOₓ) during production and use, significantly inflating the carbon and nitrogen footprint of new developments.

- Rising sustainability compliance costs make it even harder for first-time buyers and middle-income households to access new homes.

- In many regions, this material dependency slows permit approvals, constrains supply, and drives up the cost and complexity of new housing, impacting affordability and the pace of construction.

To meet growing demand for social housing while staying within ecological limits, the sector must move beyond these polluting legacy materials.

UBQ™ Materials Enable a Different Approach

UBQ™ offers a structural solution to a structural problem. As a bio-based thermoplastic composite, UBQ™ is made entirely from mixed municipal household waste, including organics and hard-to-recycle materials diverted from landfill or incineration. This not only prevents methane emissions and environmental harm at end-of-life, but also displaces carbon-intensive virgin materials at the point of use, including in the social housing sector.

Beyond its origins, UBQ™ supports a closed-loop recycling approach. It retains its mechanical properties through multiple reprocessing cycles, enabling secondary-use markets and advancing circular material flows within the construction industry. In short, UBQ™ helps builders reduce environmental impact at every stage of the material lifecycle.

More importantly, UBQ™ addresses a broad range of ecological impact categories beyond just carbon, including:

- Eutrophication Potential (EP)

Eutrophication refers to the over-enrichment of ecosystems with nutrients, particularly nitrogen and phosphorus, that can lead to algal blooms, oxygen depletion, and the collapse of aquatic ecosystems. Human activities such as fertilizer use in agriculture, sewage discharge, stormwater runoff, and fossil fuel combustion are key contributors. These processes introduce excess nutrients into rivers, lakes, and coastal waters, disrupting natural nutrient cycles and harming biodiversity. - Acidification Potential (AP)

Acidification potential measures a product’s contribution to the formation of acidifying compounds like sulfur dioxide (SO₂) and nitrogen oxides (NOₓ). These compounds can react with water in the atmosphere to form acid rain, which damages soil quality, aquatic habitats, and built environments. Fossil fuel combustion, industrial emissions, and agricultural activities are primary drivers of acidifying emissions. - Photochemical Ozone Formation (POF)

Photochemical ozone formation refers to the creation of ground-level (tropospheric) ozone through reactions between sunlight and air pollutants such as volatile organic compounds (VOCs) and nitrogen oxides. While ozone high in the stratosphere protects us from UV radiation, ozone at ground level is a harmful pollutant that contributes to smog and respiratory health problems. POF is often associated with vehicle emissions, industrial processes, and the use of certain solvents. - Ozone Depletion Potential (ODP)

Ozone Depletion Potential evaluates the impact of a substance on the breakdown of the ozone layer in the stratosphere, our planet’s shield against harmful ultraviolet (UV) radiation. Ozone-depleting substances (ODS) include chlorofluorocarbons (CFCs), halons, and other chemicals used in refrigeration, air conditioning, and aerosol propellants. These substances have been largely regulated under international agreements like the Montreal Protocol, but their legacy and replacements still contribute to ongoing environmental assessments.

These are the very indicators that underpin the Dutch nitrogen regulation framework, meaning UBQ™ helps developers meet the criteria that are currently stalling many housing projects.

And because UBQ’s environmental performance is verified through an independent third-party Life Cycle Assessment conducted by ERM, its impact is transparent and credible.

A Material Solution for Dutch Challenges

In a national housing crisis where government permitting delays and construction permits are impacting both public and private sector construction, UBQ™ offers an immediate, material-based path forward.

UBQ’s benefits extend far beyond sustainability, offering builders and manufacturers a high-quality, resilient material that integrates into existing processes and meets performance requirements.

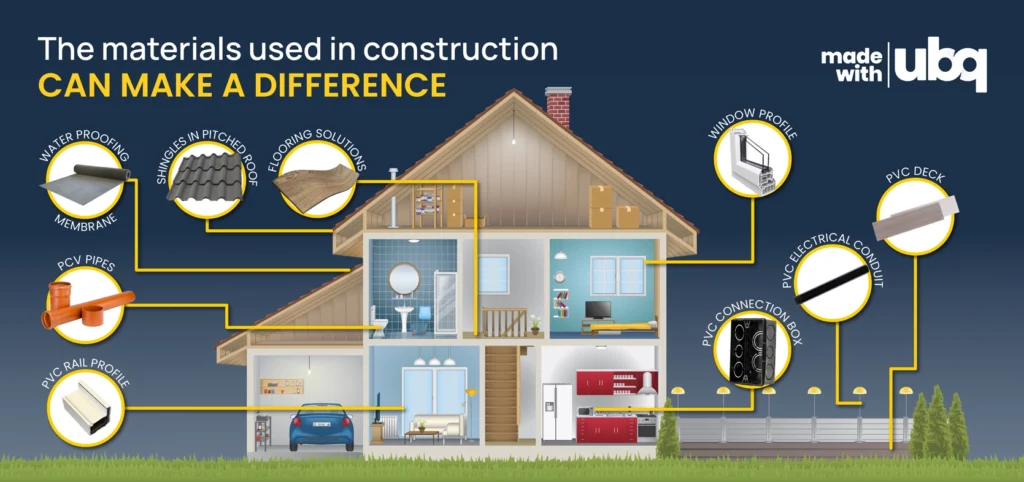

UBQ™ is compatible with most polymers, including polypropylene (PP), polyethylene (PE), and polyvinyl chloride (PVC), all essential materials in modern building and construction.

PP is commonly used in applications such as windows frames, pipes, and roofing membranes due to its durability, water resistance, and rigidity. When UBQ™ is incorporated into these formulations, it helps reduce the overall carbon footprint while maintaining the required performance standards, contributing to a more sustainable built environment.

UBQ™ has also been tested and tried in applications such as luxury vinyl flooring, fencing, protective profiles, WPC benches, PVC connection boxes, and PVC electrical conduits.

Built for a Circular Economy

The European Union (EU) and Dutch governments are pushing for a fundamental shift in the housing system, one that prioritizes:

- Recycled content

- Lower lifecycle emissions

- Displacement of fossil-based inputs

- Circularity and reusability

UBQ™ directly supports these goals, making it an ideal fit for developers navigating today’s complex Dutch housing market. It’s not just an alternative; it’s an enabler, helping projects advance despite tighter regulations and rising prices.

UBQ™ is recyclable, promoting resource conservation and advancing the circular economy. Tests by Axion Polymers (former Axion Group) show that adding UBQ™ to durable and semi-durable applications doesn’t affect the mechanical properties of recycled plastics during reprocessing.

How UBQ™ Supports The Housing Crisis

UBQ™ plays a meaningful role in making housing development more environmentally viable. It allows manufacturers and builders to reduce their reliance on fossil-based plastics, lower greenhouse gas emissions, and demonstrate climate-positive outcomes, without compromising on durability or performance.

UBQ™ is already being used in building components such as wall cladding, piping, decking, and modular construction elements. Its ability to meet regulatory benchmarks for bio-based content and emissions reduction makes it a valuable partner in navigating the sustainability expectations that increasingly shape planning approvals.

By anchoring UBQ™ within sustainability frameworks, not just carbon reduction but also waste diversion and circularity, it becomes clear that UBQ™ can help enable more sustainable housing, even if it cannot solve the entire systemic challenge alone.

Locally Made, Systemically Valuable

UBQ™ is produced locally in the Bergen op Zoom, Netherlands. This enables:

- Local waste diversion from landfill and incineration

- Fosters green job creation and regional economic resilience

- Support for economic growth and resilience in the built environment sector

By diverting municipal household waste, including food scraps, garden waste, cardboard, and soiled plastics, UBQ™ prevents these materials from entering incineration or landfill and supports developers in delivering affordable, sustainable housing at scale, while helping control environmental compliance costs in line with social equity objectives.

Verified Environmental Performance

UBQ ClimaPos™’s tablets environmental performance has been independently verified through a third-party Life Cycle Assessment (LCA) conducted by ERM, a globally recognized sustainability consultancy. This ISO-aligned study confirms the climate-positive benefits of UBQ ClimaPos™ and validates its best-in-class sustainability profile.

Key LCA results (cradle-to-gate):

- Fossil + land-use GWP: 0.15 kg CO₂e

- Biogenic carbon removal: –1.17 kg CO₂e

- Net footprint: –1.02 kg CO₂e (cradle to gate)

Addressing Rising House Prices with Sustainable Housing Development

The Dutch housing crisis isn’t just a matter of supply, it’s a complex issue involving rising house prices, environmental constraints, and a widening gap in affordable housing options. In both urban areas and suburban areas, home prices have surged beyond the reach of first-time buyers, young professionals, and even those nearing retirement age. As the growing population increases pressure on available housing, demand continues to outpace supply, especially in urban centers and economically active regions.

Compared to other countries in Europe, national house prices in the Netherlands have seen one of the sharpest increases in recent years. According to Statistics Netherlands, the average price for a newly built home has climbed steadily since the global financial crisis, with fewer dips than in many countries. While the last government introduced temporary incentives to support housing development, escalating interest rates, stricter construction permits, and limited grid capacity have slowed new construction, worsening the shortage.

Meanwhile, middle-income residents are finding their maximum borrowing capacity squeezed, even as they’re expected to spend more money to secure a place to live. These pressures are particularly acute in the private sector, where housing is increasingly unaffordable without expanded tenant protections or alternative ownership models. As the Dutch government considers potential solutions, materials like UBQ™ offer a way to unlock stalled projects, reduce climate and nitrogen impact, and support energy-efficient, circular construction, especially for the social housing sector and developments serving young people and working families.

UBQ™’s local production also supports the broader goals of economic growth, job creation, and decentralization of opportunity into rural areas, helping balance regional housing disparities and reduce dependency on limited land in overburdened cities.

Ready for Use in Building Materials

UBQ™ is already being applied in sectors relevant to housing construction. It can substitute or reinforce conventional plastics in:

- Panels and boards

- Flooring and Roofing

- Construction profiles and pipes

- Decking, cladding, and outdoor furniture

UBQ™ can be used in combination with other plastics depending on the mechanical and visual requirements of the end product. This makes it a solution for existing supply chains, minimizing time to market while maximizing compliance.

UBQ vs. Other Circular Building Materials

Across the Netherlands, several bio-based and circular materials are being piloted in the housing sector, including:

- Hempcrete, which is low-carbon but still limited in structural applications.

- Mycelium-based insulation, promising but still emerging at an industrial scale.

- Recycled concrete and geopolymer cements, which help reduce carbon but do not directly address nitrogen-related impacts from material production.

- Cross-laminated timber (CLT), gaining traction but challenged by supply and fire codes, as well as higher costs, lower acoustic and thermal insulation, and more complex design integration.

While these innovations contribute to circularity, many are still niche, location-dependent, or awaiting regulatory standardization.

UBQ™ stands out by being:

- Already commercially available

- Locally produced in the Netherlands

- Compatible with existing manufacturing processes

- Effective in carbon reduction

- Suitable for a wide range of components in housing construction

For housing projects on tight timelines and stricter compliance thresholds, UBQ™ offers a commercially available, ready-to-use material solution backed by third-party-verified climate and ecological benefits, not just a concept or pilot. UBQ is produced in the Netherlands.

Building Forward with UBQ™

The Netherlands is at a crossroads. Delivering affordable housing to meet urgent housing demand must now go hand-in-hand with meeting strict environmental thresholds, particularly around nitrogen and carbon emissions. Traditional materials and methods are no longer sufficient. They slow down permitting, drive up costs, and contribute to the delays that have put nearly a third of planned housing supply at risk. UBQ™ offers a way forward.

By turning waste into a climate-positive material, UBQ™ enables housing developers to reduce emissions at the material level and unlock stalled or constrained projects, all while supporting circular economy goals, local production, and green job creation.

Where other sustainable materials are still being piloted, UBQ™ is ready now, scalable, and designed to integrate with existing infrastructure. It addresses not only the need to build more homes but to build them in a way that aligns with the Netherlands’ most pressing environmental and social imperatives.