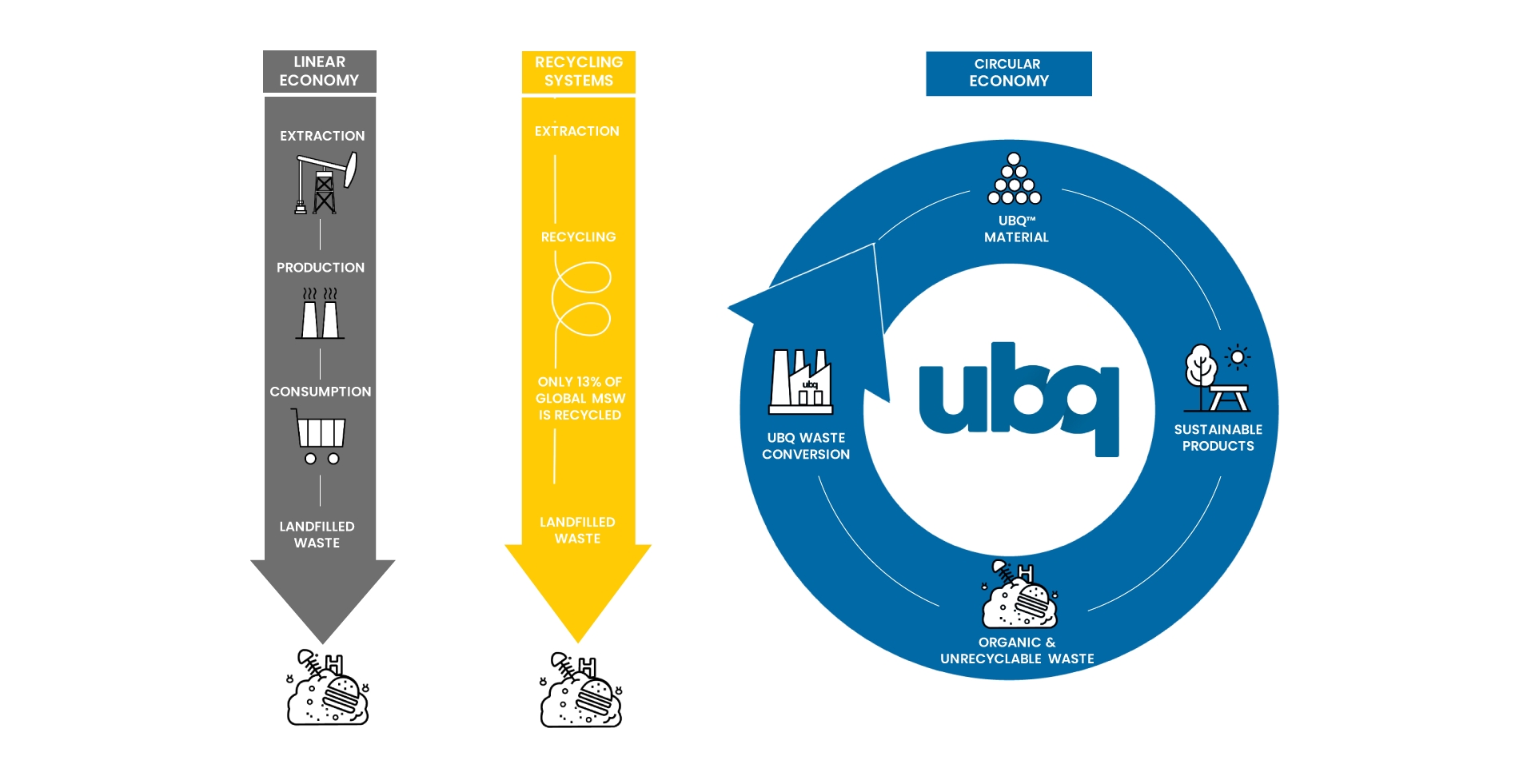

UBQ Materials offers a solution to the growing waste crisis by unlocking the hidden value of waste.

The patented UBQ conversion process begins with the receipt of residual municipal solid waste; everything from food residues and mixed plastics to cardboard, paper, and even dirty diapers, that would have otherwise been sent to landfill or incineration. Metals and minerals, which have high recyclability, are removed and sent over to traditional recycling streams. All that remains is transformed into UBQ™ – so nothing goes to waste.

The sole feedstock to the UBQ™ conversion process is household waste, which is largely comprised of organic materials. UBQ’s advanced waste conversion technology breaks down the organic matter into its basic particulate constructs—lignin, cellulose, fibers, and sugars—and then reassembles them into a matrix. Residual plastics present in the waste stream melt and get mixed into the matrix to create a homogeneous and consistent composite thermoplastic material.

As opposed to conventional chemical recycling systems that utilize high temperatures to break apart polymer bonds of synthetic plastics, UBQ requires significantly lower temperatures and energy. In 2021, UBQ’s solar array generated 100% of the energy required to produce UBQ™.