September 2, 2020 — UBQ Materials, an Israeli-based cleantech company, has announced its plans to establish its first full-scale production facility in the Netherlands.

UBQ Materials has developed a patented process to convert landfill-destined waste into a sustainable, bio-based thermoplastic material. This novel climate-positive material can substitute conventional plastic, wood and concrete in the manufacturing of thousands of everyday products. UBQ™ is a proprietary composite, the world’s first bio-based material made of unsorted organic, paper and plastic waste – everything from banana peels to dirty diapers to used yoghurt containers and cardboard. The central value proposition of using UBQ™ is its sustainability metrics, significantly reducing and even neutralizing the carbon footprint of final applications.

By diverting household waste from reaching landfills, UBQ Materials prevents the emission of methane, groundwater leakage and other toxins. According to Quantis, a leading provider of environmental impact assessments, every ton of UBQ Material produced offsets 11.7 tons of CO2 equivalent, qualifying it as ‘the most climate-positive thermoplastic material on the planet.”

The establishment of the facility follows the EU’s decision to support the development of sustainable industries, striving to increase the use of environmentally sound plastic alternatives. Moving closer to its customers, UBQ™ will be sold across Europe and exported to countries around the world, further reducing the transportation-related carbon footprint of businesses and consumers alike.

To officially mark the global expansion, the Netherlands’ ambassador to Israel, Hans Docter, visited and toured UBQ’s existing facility in Kibbutz Tse’elim, Israel on September 9th.

The Netherlands facility will have an annual production output of 80,000 tons of UBQ™. This versatile material can be used in the manufacturing of thousands of products, everything from construction goods like pipes, bricks, floors, roofing and panels; supply chain logistics like shipping pallets, bins, crates, shopping carts and display units; UBQ™ is even being used in furniture, auto parts and 3D printing.

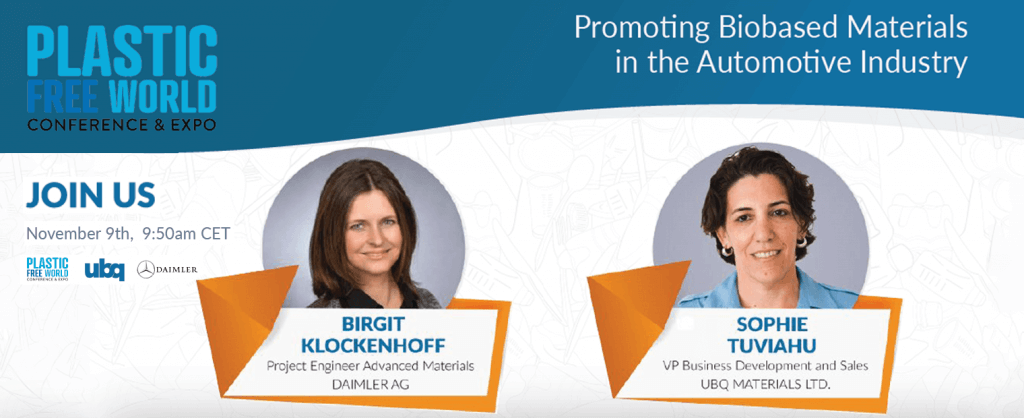

In early 2020, the company announced its collaboration with Daimler, the manufacturer of Mercedes-Benz, for the implementation of UBQ™ in car parts. Additional partnerships with leading brands in fashion, retail, logistics and FMCG are underway and with expected announcements to be released in Q1 2021.

About UBQ Materials

UBQ Materials was founded in 2012 by entrepreneurs Rabbi Yehuda Pearl and Tato Bigio. A certified B-Corp, Israel-based UBQ Materials envisions a world where finite resources are infinitely reused. UBQ makes household waste a renewable resource. Through its patented process, unsorted waste becomes UBQ Material, an infinitely renewable thermoplastic resource with ever-expanding applicability. Learn more about UBQ Material on its website, Facebook, LinkedIn, Twitter, and Instagram.