TEL AVIV, Israel – February 1, 2022 – UBQ Materials, cleantech developer of advanced materials made from waste, today announced a partnership with Resirene, the largest Polystyrene resin producer in Mexico, to produce the first worldwide circular grade high-impact polystyrene (HIPS) compound with UBQ™ inside, which will make it the most sustainable in the world.

Resirene, a large polymers producer, serves numerous market segments, including polymer applications for food & beverage, healthcare and medical products, electronics, construction and advertising, among others. The company has made significant R&D and production investments as it foresees increased demand for sustainable products. UBQ™ will be used in higher-value items ranging from multi-use razor handles to signage.

“The plastic-free movement, including government regulations banning products such as single-use straws and plastic bags, has propelled the polystyrene market to adapt and evolve. There is now a continuum of sustainability within polystyrenes, ranging from starch-containing products to those made with recycled polystyrene,” said Sergio Paredes Castañeda, CEO of Resirene. “We have reached a new level in terms of reducing our product’s environmental impact with UBQ™ inside, thereby allowing our customers to jointly achieve sustainable loans, enabling the polystyrene industry to strive as a whole towards circular economies,” the executive mentioned.

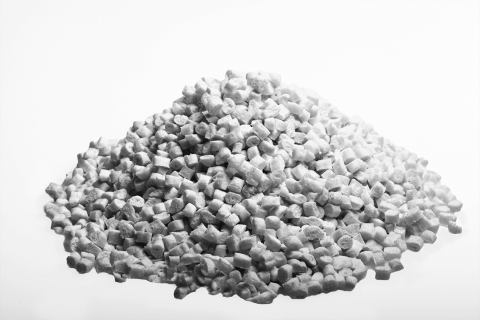

UBQ Materials converts unsorted household and municipal landfill-destined waste into UBQ™, a climate-positive, cost-competitive replacement for plastic. UBQ™ is a bio-based drop-in material that can be incorporated into standard manufacturing processes without additional machinery or materials. The production of UBQ™ decreases the landfilling of waste, preventing methane emissions and curtailing the leakage of toxic substances into the soil.

“The ‘lifecycle’ of products is a misnomer – until now, products were manufactured, used, and discarded – not a cycle at all, but rather a straight line. Our goal is to close the loop on the production-to-waste process and create a circular economy that takes the seemingly endless accumulation of waste and converts it into a resource,” said Albert Douer, Chairman and co-CEO of UBQ Materials. “This partnership with Resirene allows us to incorporate our climate-positive thermoplastic into various products, offsetting emissions and offering a viable end-of-life solution for waste.”

After extensive R&D trials and testing to develop the new material with UBQ™, Resirene has already started to sample the new material with clients. Initial results suggest that customers find the added environmental value meaningful, even when one accounts for the variable of product costs.

About UBQ Materials

UBQ Materials Ltd. has developed an advanced conversion technology, patenting the world’s first bio-based thermoplastic (UBQ™) made entirely of unsorted household waste, a revolutionary way to divert municipal solid waste from landfills and convert it into a sustainable substitute for oil-based plastics. A certified B Corp, UBQ is a recent recipient of the 2020 Future of Plastics Award and 2020 Quality Innovation Awards. UBQ’s customers include global retail solutions provider Mainetti, Daimler, the manufacturer of Mercedes-Benz, and Arcos Dorados, the world’s largest franchisee of McDonald’s restaurants across Latin America.

With a climate-positive impact and cost-competitive price, UBQ™ empowers manufacturers with a simple transition to greater sustainability. Learn more by visiting UBQMaterials.com.

About Resirene

Resirene is a Mexican company with over 40 years of experience and leadership in the polystyrene industry, focusing on innovative and sustainable solutions to support the transition to a circular economy. With a production capacity of more than 170,000 tons per year, it is the most prominent Mexican producer of Crystal Polystyrene (GPPS), High Impact Polystyrene (HIPS), and Styrene-Methyl Methacrylate (SMMA) copolymers, with applications for a broad range of industries, including packaging, electronics, household, construction, and healthcare.

International Media Contact

Nicole Kaufman Grubner

FINN Partners

929-588-2011

nicole.grubner@finnpartners.com