What You’ll Learn

- The difference between embodied and operational carbon

Understand how emissions are generated during construction and building use, and why it matters for lifecycle impact. - The role of materials in construction’s carbon footprint

Learn why low-carbon and circular alternatives like UBQ™ are essential for reducing emissions at scale. - How to use tools like LCA, EPDs, and PCFs for emissions tracking

Explore carbon accounting methods that support transparency, compliance, and better material decisions. - Actionable strategies for low-carbon construction

Discover practical ways to reduce your project’s footprint, from smarter design to renewable energy and landfill diversion.

As one of the largest emitters worldwide, the construction industry sits at the epicenter of the global climate conversation, nearly 40% of global greenhouse gas emissions are linked to construction and real estate, encompassing both the materials used and the energy required to power buildings over their lifetime. From towering skyscrapers to sprawling infrastructure, each decision made today casts a long environmental shadow that will persist across decades.

Long-term Impact of Building and Infrastructure Decisions

The long-term environmental consequences of construction are significant and far-reaching. According to the World Green Building Council, the global building stock is expected to double by 2050, just as the world’s population approaches 10 billion. Without immediate intervention, upfront carbon emissions, those released before a building is even occupied, could account for half the carbon footprint of all new construction between now and mid-century. These decisions made today will lock in emissions profiles for decades to come, threatening to consume a large portion of the world’s remaining carbon budget.

In response, global initiatives like the WorldGBC’s Advancing Net Zero project are calling for systemic change: targeting at least a 40% reduction in embodied carbon by 2030, and net zero embodied and operational carbon by 2050. Infrastructure is no longer a neutral investment; it’s a frontline climate decision with generational consequences.

Breaking Down Construction’s Carbon Footprint

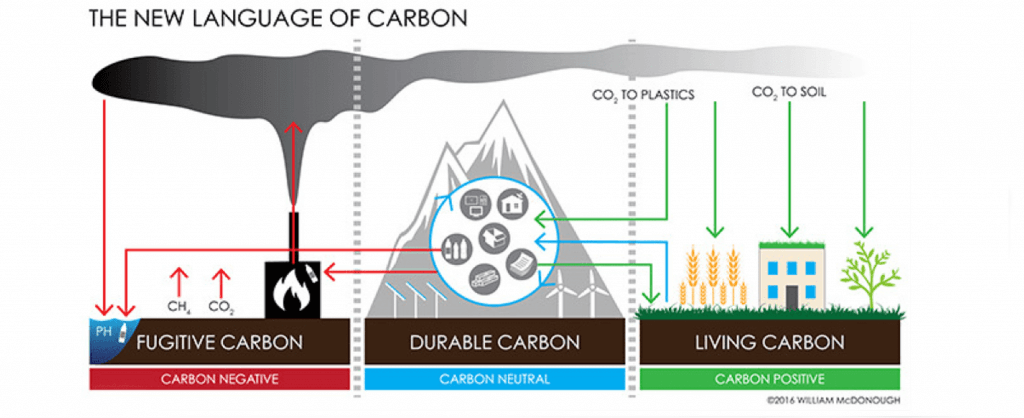

To decarbonize construction effectively, it’s essential to distinguish between embodied carbon and operational carbon, the two primary sources of emissions in the built environment.

Embodied carbon

Embodied carbon refers to greenhouse gas emissions associated with raw material extraction, manufacturing, transportation of materials, as well as construction processes. Emissions that are locked in long before a building is ever occupied cannot be reversed.

Operational carbon

In contrast, operational carbon encompasses the emissions generated throughout a building’s use phase, from heating and cooling to lighting and power consumption. While these emissions occur over time and can be mitigated through energy efficiency and renewable sources, they represent only part of the total carbon profile.

Separating these two carbon profiles is critical. Embodied and operational emissions require different strategies and timelines for reduction. Addressing them in parallel enables the construction sector to achieve meaningful, lifecycle-wide decarbonization and ensures that today’s material and design decisions align with long-term climate goals.

Life Cycle Assessment (LCA) in Construction

Life Cycle Assessment (LCA) is the scientific method used to quantify environmental impacts, including carbon footprint, throughout all stages of a product’s life. LCAs are foundational for identifying carbon ‘hot spots’ and guiding material selection, as they encompass not just cradle-to-gate or cradle-to-grave, but every relevant impact category by design.

As the scientific backbone for carbon reporting and product selection, LCA enables construction stakeholders to make informed, data-driven decisions. To communicate LCA results effectively, the sector relies on two key reporting tools: Environmental Product Declarations (EPDs) and Product Carbon Footprints (PCFs).

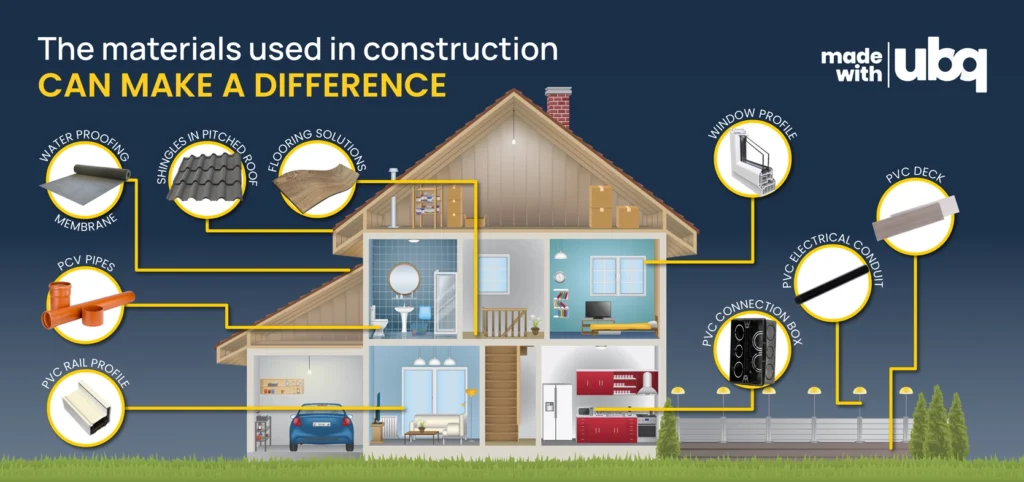

Materials Matter: The Carbon Cost of Construction Inputs

Construction materials are among the most carbon-intensive products on the planet. Cement, steel, and conventional plastics carry heavy environmental footprints due to energy-intensive production processes and reliance on virgin, fossil-based resources. Together, these inputs contribute significantly to the embodied carbon of buildings and infrastructure.

As the industry shifts toward decarbonization, the spotlight is turning to material replacement, specifically, the adoption of bio-based and circular alternatives that reduce emissions without compromising performance.

UBQ™ offers a breakthrough solution with its product portfolio. UBQTM is a bio-based thermoplastic material that offers sustainable and practical solutions for applications where function is more important than form or flash, like in the building and construction or the logistics and supply chain industries. Additionally, UBQ ClimaPos™, a bio-based sustainability additive that goes a long way toward achieving your sustainability targets, is a replacement for conventional plastics in durable and semi-durable applications that can be used inside or outside buildings and infrastructure.

Decarbonization: The Industry’s Defining Challenge

Selena Group experts state that decarbonizing construction is impossible without reducing the carbon footprint of building materials, and the data support this view. In many new buildings, embodied carbon from materials and construction activities often outweighs the operational carbon saved through efficiency measures over time. As a result, materials have become a focal point in the effort to reduce emissions across the built environment.

UBQ™ directly supports this shift. By converting landfill and incineration-bound municipal waste into climate-positive thermoplastic materials, UBQ™ provides a viable replacement for fossil-based plastics and composites in construction. This not only diverts waste but also removes emissions by temporarily storing biogenic carbon for the product’s lifespan, helping projects reduce embodied carbon from the outset.

UBQ™ is already being used in construction applications such as piping, cladding, roofing membrane, and panels, offering performance alongside environmental benefits.

In this context, decarbonization is not just a compliance issue; it’s a strategic advantage. Adopting climate-positive materials like UBQ™ positions companies ahead of regulatory pressure, while aligning with market demand for low-carbon construction solutions.

Supply Chain & Carbon Accounting in Construction

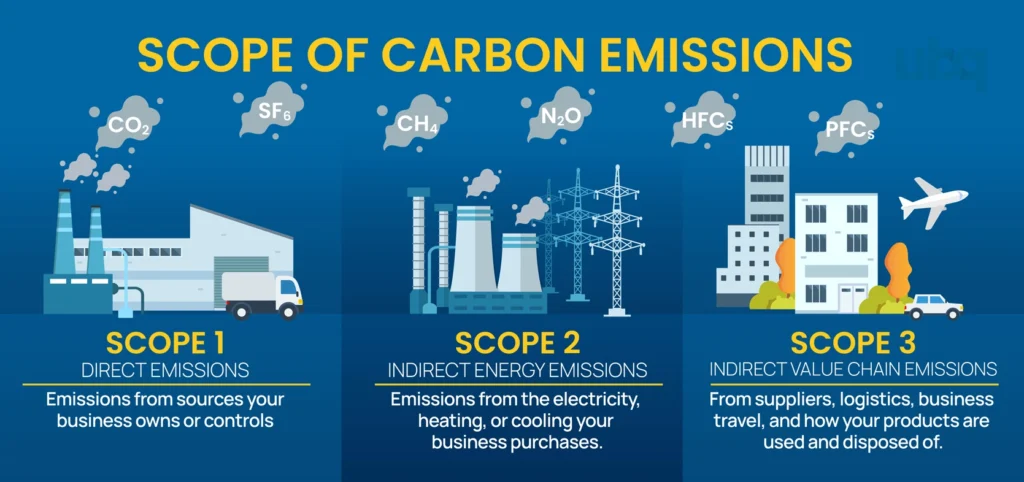

Understanding and reducing emissions across the construction supply chain requires a clear grasp of Scope 1, 2, and 3 emissions:

- Scope 1: Direct emissions

Emissions from sources your business owns or controls, like fuel use in company vehicles or heating your premises. - Scope 2: Indirect emissions from energy

Emissions from the electricity, heating, or cooling your business purchases. They happen off-site but result from your energy use. - Scope 3: Indirect emissions across your value chain

All other indirect emissions, from suppliers, logistics, business travel, and how your products are used and disposed of. Typically, the largest share of your emissions.

Reducing construction’s full carbon impact requires managing all three scopes collaboratively with suppliers. Together, this builds the full emissions inventory for projects and for the company as a whole.

To manage these emissions effectively, it’s essential to distinguish between the key tools used in carbon accounting:

- Life Cycle Assessment (LCA) is the scientific method for evaluating a product’s environmental impacts across its entire lifecycle.

- Environmental Product Declarations (EPDs) are standardized, third-party verified reports that communicate a product’s environmental performance based on LCA data.

- Product Carbon Footprints (PCFs) are focused specifically on the total greenhouse gas emissions associated with a product throughout its lifecycle.

- GHG Protocol to structure Scope 1-3 reporting: comprehensive global standard for measuring, managing, and reporting greenhouse gas emissions.

Together, these tools ensure transparent and consistent reporting of carbon impacts, enabling better material choices and compliance with sustainability targets.

Suppliers play a pivotal role in the total carbon footprint of a construction project. Their material sourcing, manufacturing processes, and data transparency directly affect Scope 3 emissions, and, by extension, a project’s overall sustainability performance.

To support accurate reporting and reduction strategies, the industry increasingly relies on digital tools and frameworks such as the GHG Protocol, ISO standards, and EPD databases. These systems provide the structure and credibility needed to track progress, validate claims, and align with international decarbonization goals.

How Construction Companies Can Reduce Their Footprint

Material Swaps: Bio-Based, Climate-Positive Replacements (UBQ™)

One of the most immediate ways to reduce embodied carbon is by replacing traditional, fossil-based materials with bio-based, climate-positive alternatives like UBQ™. Made from municipal solid waste, including organics, UBQ™ serves as a thermoplastic replacement that not only lowers emissions but actively prevents them. Swapping conventional plastics with UBQ™ contributes to decarbonization goals without compromising performance or compliance.

Smarter Design: Modularity, Lightweighting, Prefabrication

Incorporating smarter design strategies, such as modular construction, lightweight materials, and prefabricated components, can significantly reduce material use, minimize waste, and optimize transportation. These methods lower both embodied and operational carbon while streamlining project timelines.

End-of-Life Considerations: Waste Diversion and Landfill Avoidance

Construction companies must also plan for the end-of-life (EOL) phase of materials. UBQ™ offers a compelling example: by transforming landfill and incineration-bound waste into reusable material, UBQ™ helps remove methane emissions and supports circularity. Prioritizing materials with strong waste diversion potential aligns with certification frameworks like LEED and BREEAM, which reward circular and low-impact solutions.

Renewable Energy in Construction Operations

Switching to renewable energy, such as solar or wind, for on-site operations and equipment use can drastically cut Scope 1 and Scope 2 emissions. Integrating clean energy not only supports decarbonization efforts but also enhances a project’s overall environmental profile and eligibility for green building certifications.

Case Studies & Industry Examples

UBQ™ is already being implemented in real-world construction projects, demonstrating its effectiveness as a low-carbon material in durable applications. It has been successfully tested in roofing membrane, luxury vinyl flooring, cladding systems, and piping infrastructure, and used in board panels to remodel kitchens and bathrooms, where it replaces conventional plastics with a climate-positive alternative, reducing embodied carbon without compromising performance or compliance.

At the same time, green building certifications such as LEED and BREEAM are accelerating the industry’s shift toward low-impact materials. These frameworks encourage the use of verified low-impact materials, and UBQ™ helps projects meet certification goals by reducing carbon and diverting waste.

Looking Ahead: The Future of Low-Carbon Construction

The regulatory landscape is rapidly evolving to support climate action in the built environment. Policies such as the EU Green Deal, carbon disclosure mandates, and the development of an EU-wide standard for certifying permanent carbon removals are setting new expectations for transparency, accountability, and long-term impact. In construction, this includes increasing recognition of carbon storage in materials, particularly those that lock in emissions for over 35 years, as seen in certain durable building products.

As these frameworks take hold, climate-positive materials are moving from niche innovations to standard inputs. The construction industry is beginning to prioritize materials that not only reduce emissions but also actively prevent or remove them. This shift marks a fundamental change in how buildings are designed and built, one where sustainability and performance go hand in hand.

Final Thoughts

The construction industry’s carbon footprint is driven largely by the raw materials used and the embodied carbon emissions locked into them. To reduce the construction carbon footprint and achieve meaningful progress in reducing carbon emissions, the sector must focus on low-impact materials. As infrastructure expands, so does the urgency to reduce embodied carbon, cut operational carbon emissions, and limit carbon dioxide released during production.

Reducing embodied carbon emissions is critical to addressing climate change and limiting global warming. UBQ™ helps reduce embodied carbon by converting waste into sustainable construction materials, replacing raw materials and avoiding landfill and incineration emissions. This approach supports energy-efficient design, enables carbon reduction across the life cycle, and moves the construction sector closer to net zero.