Have you heard the terms “circular economy” or “circularity” but not known exactly what they mean? To understand it, it might help to start with the opposite of the circular economy: the linear economy.

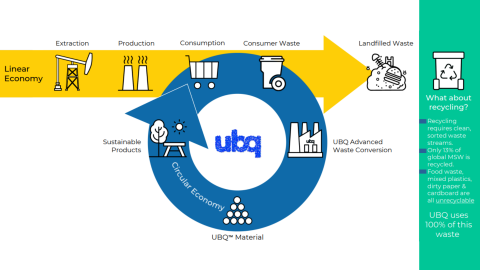

Picture what happens to a lot of products now. First, the basic materials are mined, harvested, or extracted, like trees for paper products or oil for plastics. Then, the product is manufactured, purchased and used by customers, and thrown away. Some things are recycled, but not enough—in fact, more than 90% of all the things we make are used and discarded. Think of this system, sometimes described as “take, make, waste”, as a straight line. The idea of the circular economy, essentially, is to make the line into a circle so that when we’re done with items, they can be either repaired, reused, recycled, or returned to nature as nutrients.

The Ellen MacArthur Foundation, established by the renowned UK world sailing champion on June 24, 2009, was created to advance a comprehensive circular economy system at the micro and national levels, and since then has led to some of the most well-known models within this system (suggested read—see link below).

Sustainability throughout the supply chain goes beyond conserving an ecological balance. Brands and manufacturers that employ a zero-waste supply chain model are finding new ways to meet a growing consumer demand for sustainability while improving productivity and profitability.

UBQ Materials‘ patented waste conversion process transforms unsorted landfill-destined waste into a novel thermoplastic material that can replace oil-based plastics in the manufacturing of a vast range of durable products. UBQ is helping brands and manufacturers in multiple industries (such as construction, retail, food and beverage, automotive within others) meet their sustainability goals. UBQ’s bio-based material is brining industries closer to a truly circular economy and is already being used by leading brands such as Mercedes-Benz, McDonalds, ABinBev, PepsiCo, and many more.

Achieving a circular economy is not only possible but beneficial. The recycling industry is far from perfect, yet technologies exist and we believe UBQ can be part of the missing link in closing the cycle. By integrating environmentally and financially viable practices in the supply chain lifecycle, organizations can reduce their total carbon footprint and optimize their end-to-end operations to achieve greater cost savings and profitability. We’re pleased to play a role in helping companies eliminate waste in their supply chains and meet their sustainability goals.

UBQ was designed to be at the bottom of the waste hierarchy—if something can be repaired or recycled, these options should come first, and we want to see those systems developed and improved. However, in the linear economy, most products are either disposed in landfills or open dumps, incinerated for energy, or simply burned. It’s these polluting activities that UBQ intends to replace by upcycling residual waste into a valuable thermoplastic material.