We all want to do our part to protect the planet. But when it comes to managing waste and choosing sustainable options, the terms recycling, repurposing, and reusing are often used interchangeably or misunderstood entirely.

In 2016, the Ellen MacArthur Foundation published a landmark report revealing that most plastic packaging is used only once, and just 14% is collected for recycling. Shockingly, 95% of the value of plastic packaging material, worth between USD 80–120 billion annually, is lost to the global economy.

Their second report, released in 2017 with industry partners, took this further. It concluded that without fundamental redesign and innovation, around 30% of plastic packaging will never be reused or recycled. In other words, even the best recycling systems can’t fix the problem alone.

The 3 R’s is usually used to refer to “reduce, reuse, recycle”, as these were the original three concepts that were popularized to reduce the environmental impact of consumption. However, many more R options have been added as the circular economy model has been developed, including “repurpose”.

Each of these strategies plays a role in reducing plastic pollution, conserving resources, and cutting emissions. But which is truly the most effective, and where does a breakthrough like UBQ™ fit into this picture?

Let’s break it down.

What Does Recycling Really Mean?

Recycling is the process of collecting, processing, and breaking down waste materials into secondary raw substances so they can be remade into new products. For example:

- Melting down plastic bottles to create synthetic fibers

- Turning crushed glass back into containers

- Reprocessing aluminum cans into new metal products

Before sorting, recycling starts with source separation into different streams for curbside programs, drop-off centers, or collection points. Waste is further sorted in the material recycling facility and then cleaned to remove contamination (e.g., food residue, mixed materials) that can ruin entire batches. Then, recyclables are shredded, melted, or pulped, and turned into secondary raw materials (e.g., plastic pellets, paper pulp, aluminum ingots) that manufacturers use to create new products.

While recycling sounds like a perfect solution, it has its limits, particularly when it comes to plastic waste. Many plastics can’t be recycled at all, and even recyclable plastics degrade over time, resulting in downcycling: lower-quality products with limited future use.

Contamination, inconsistent sorting systems, and economic factors often lead to materials being sent to landfills or incinerators anyway, especially plastic packaging and plastic polymers.

What Is Reusing?

Reusing means taking a product and using it again, either for its original purpose or a similar one, without major processing. This could include:

- Refilling a water bottle instead of tossing it

- Giving outgrown children’s clothes to a friend with younger children

- Using durable containers instead of single-use plastics

Reusing is one of the most sustainable practices because it delays or avoids the need for new production entirely. It conserves raw materials, reduces the need for plastic production, and helps keep plastic products out of the waste stream.

However, it depends heavily on consumer behavior, logistics, and product design. Items need to be built to last, users must be willing to adopt reuse practices consistently, and businesses must facilitate reuse.

What Is Repurposing?

Repurposing involves taking an item and giving it a new function, different from what it was originally intended for. Think of it as a creative form of reuse (DIY upcycling).

Examples include:

- Turning old jeans into a tote bag

- Using a jam jar as a plant pot

- Repurposing industrial offcuts into building materials

Repurposing helps reduce waste and inspires innovative thinking, particularly in design and manufacturing. It also helps keep larger plastic debris and non-biodegradable waste out of landfills by giving it added value.

How Do These Compare in Terms of Sustainability?

In general, there’s a hierarchy of impact:

- Reusing – Most sustainable, as it is easiest (just use it again) and avoids new production

- Repurposing – Creative and waste-reducing, but limited by scale

- Recycling – Necessary, but energy-and water-intensive and often expensive and inefficient

All three approaches have value, and the most effective sustainability strategies use them in combination. They all reduce new production and at least delay disposal, although they may not keep materials out of landfills and incinerators indefinitely.

Where Does UBQ™ Fit In?

What about the materials that can’t be reused, repurposed, or recycled, things that fall through the cracks in the system? This is where UBQ Materials changes the equation.

UBQ Materials is a global manufacturing company that has developed a patented technology that goes beyond recycling, reusing, or repurposing. It converts mixed household waste, including food scraps, dirty plastics, cardboard, and other hard-to-recycle items, into UBQ™, a bio-based thermoplastic composite. Unlike traditional recycling systems, which depend on clean, separated waste, UBQ™ can use unsorted waste, including organic content like banana peels and chicken bones, to create a durable material for manufacturing.

Verified Environmental Performance: The Role of Life Cycle Assessment

To ensure the environmental benefits of UBQ™ are clear and measurable, the company commissioned a full Life Cycle Assessment (LCA) to ERM, a multinational consultancy firm focused on sustainability and the environment, headquartered in London, United Kingdom.

This verified third-party LCA found that each kilogram of UBQ™ tablets removes 1.17 kilogram CO2eq of biogenic carbon due to the conversion of organic waste into UBQ™, with a production carbon footprint of only 0.15 kilograms CO2eq per kilogram UBQ™ tablets. This results in a net cradle-to-gate carbon footprint of -1.02 kilograms CO2eq per kilogram UBQ™ tablets.

Additionally, every kilogram of UBQ™ produced in Bergen op Zoom, the Netherlands, diverts 1.5 kilograms of waste from landfills and incinerators, significantly reducing greenhouse gas emissions and contributing to a circular economy.

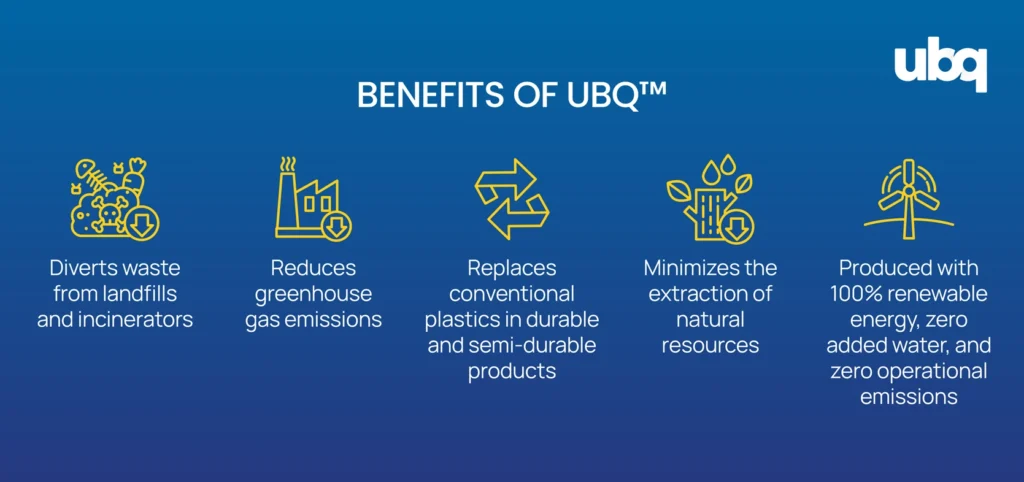

Benefits of UBQ™:

- Diverts waste from landfills and incinerators

- Reduces greenhouse gas emissions

- Replaces conventional plastics in durable and semi-durable products

- Minimizes the extraction of natural resources

- Produced with 100% renewable energy, zero added water, and zero operational emissions

By turning what was once considered hard-to-recycle into a high-value, climate-positive bio-based thermoplastic, UBQ™ offers a solution that supports a truly circular economy. It enables manufacturers to integrate sustainability into their products from the ground up by finding value in what others take for granted.

Learn more about how UBQ is pioneering sustainable building materials.

Final Thoughts: Why the Future Is Circular, Not Linear

Recycling, repurposing, and reusing each play an important role in sustainability. But the deepest impact comes from moving beyond the linear “take–make–waste” model toward a truly circular system—one that prevents waste in the first place, designs products thoughtfully, and keeps resources cycling at their highest value for as long as possible.

UBQ™ doesn’t compete with recycling, it complements and strengthens it. By transforming landfill-bound residual waste into a recyclable, bio-based thermoplastic substitute, UBQ Materials turns the most challenging discarded materials into valuable raw ingredients. Products made with UBQ™ can be reintroduced into existing recycling streams, extending their life and impact.

This is more than waste management, it’s waste re-imagined. Scalable, cost-competitive, and climate-positive, UBQ™ empowers manufacturers to reduce dependence on finite, fossil-based resources while creating products designed for circularity from the very beginning.

The best choice for the planet isn’t only about how we dispose of things; it’s about rethinking how we make them, ensuring that every end-of-life is also a new beginning.