Key Takeaways

- Why recycling isn’t enough to address the emissions impact of today’s waste streams.

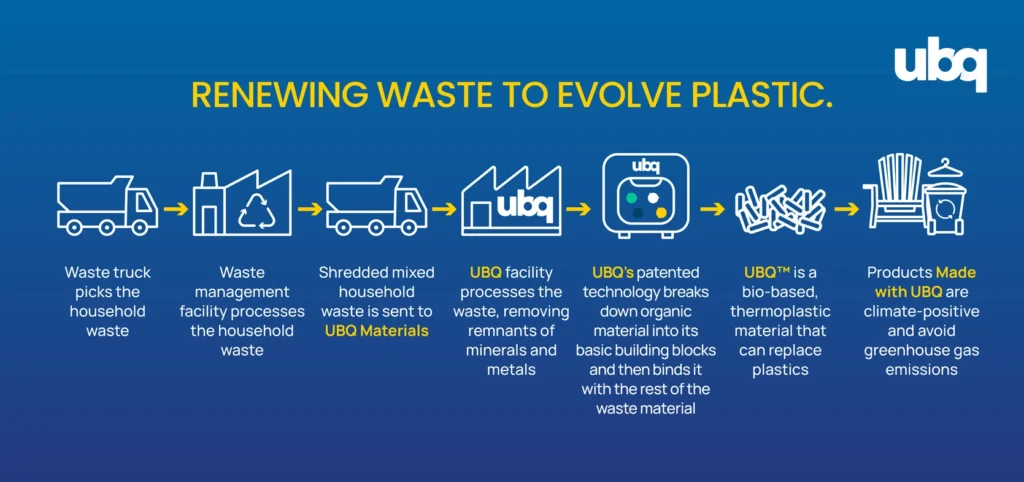

- How UBQ’s process transforms landfill-bound waste into a sustainable raw material.

- The role waste-derived materials can play in reducing Scope 3 emissions and supporting circularity.

As the urgency of climate change accelerates, decarbonization has become a global imperative. From renewable energy sources and energy efficiency improvements to innovative carbon removal technologies, decarbonization strategies are shaping our path to achieve net-zero targets under the Paris Agreement.

At UBQ Materials, we see waste as an overlooked frontier for decarbonization. Our pioneering technology converts mixed municipal waste, including organic waste like banana peels and chicken bones, into UBQ™, a climate-positive thermoplastic composite.

This article explores how UBQ’s process goes beyond recycling, contributing to decarbonization by diverting waste, reducing greenhouse gas (GHG) emissions, and supporting a circular economy in regions like the European Union (EU), the United States (US), and the United Arab Emirates (UAE).

The Role of the Waste Crisis and Its Climate Impact

The world is facing an escalating waste crisis, with over 2 billion tonnes of municipal solid waste generated annually, projected to rise to 3.4 billion tonnes by 2050 driven by population growth and increasing consumption. This surge in waste generation places immense strain on existing waste management practices.

Currently, the dominant disposal methods in the EU, landfilling and incineration, remain key contributors to greenhouse gas (GHG) emissions. Landfills are the largest source of methane emissions within the EU waste sector, responsible for approximately 80% of sectoral methane emissions in 2020. While emissions have declined due to improved recycling, landfill gas recovery, and energy recovery from incineration, further reductions are needed to meet the EU’s climate goals.

Incineration of non‑hazardous municipal waste in the EU has increased sharply, rising by about 11% between 2010 and 2022, and nearly doubling (+96%) since 1995, now accounting for roughly 56 million tonnes in 2022. While incineration reduces landfill use and produces energy, it remains a less preferred option in the EU waste hierarchy due to air pollutant emissions such as dioxins, NOₓ, and particulate matter. Emissions from incinerators have shown mixed trends over the past decade, but have stabilized since around 2017, thanks in part to the uptake of Best Available Techniques (BAT). Legal reinforcement came in late 2023 with binding BAT conclusions, and the revised Industrial Emissions Directive (effective 2024) is expected to further drive down incineration-related pollution.

In addition, incinerations are not circular. The European Union has ambitious circularity goals centered on transitioning to a fully circular economy by 2050, with important milestones and actions expected by 2025 to keep on track. The EU’s circular economy agenda is a key part of the European Green Deal and aims at reducing waste, increasing recycling and reuse, promoting sustainable product design, and keeping materials circulating within the economy for as long as possible.

In the UAE, landfilling remains the dominant waste disposal method across the UAE and the wider Gulf Cooperation Council (GCC) region, making it a significant contributor to greenhouse gas (GHG) emissions. Methane from landfills, 86 times more potent than carbon dioxide over 20-year horizon, is a major environmental concern. However, efforts are underway to mitigate this impact. At Dubai’s Al Qusais landfill, Green Energy Solutions & Sustainability LLC has implemented the region’s first landfill gas-to-energy project, capturing and flaring methane that would otherwise escape into the atmosphere. The project reduces emissions by over 300,000 tonnes of CO₂ equivalent annually and supplies power to municipal facilities, setting a regional benchmark for sustainable waste management.

The methane capture rate at the Al Qusais landfill in Dubai during the first year is approximately 20% of the total methane gas produced by the landfill. This is based on the fact that the current gas recovery system captures and flares about 6,000 cubic meters of landfill gas per hour, with a methane content of roughly 55-58%, and the system covers about 20% of the landfill’s total methane production as of the latest available data.

Equally important is the conservation of resources already in circulation. By designing systems that keep materials in use for as long as possible – through reuse, repair, and reintegration into manufacturing, industries can lower demand for virgin raw materials, reduce energy use, and cut greenhouse gas emissions. This approach ensures that the maximum value is extracted from every resource before it reaches the end of its life, creating a more resilient and efficient material economy.

What is Decarbonization?

Decarbonization is the process of reducing carbon dioxide (CO₂) and GHG emissions referred to as CO2eq emissions across all sectors of the economy with the goal of limiting global warming, mitigate the impacts of climate change, and advancing a transition towards a low-carbon future. It involves transforming how we produce energy, manufacture goods, transport people and products, and manage natural and industrial resources, reduce waste, and mitigate the impacts of global warming, and ensure a more sustainable future.

Key sectors involved in decarbonization include:

Energy production

Shifting away from fossil fuels such as coal, oil, and natural gas towards renewable energy sources like solar, wind, geothermal, and hydropower, to build a more clean, resilient, and sustainable energy system.

Industry

Energy and material efficiency improvements, adopting low-carbon technologies, and reducing reliance on carbon-intensive processes and materials.

Transportation

Accelerating the shift to electric vehicles and sustainable fuels (e.g., hydrogen, biofuels), and low-emission logistics systems to reduce GHG emissions from mobility.

Waste management

Minimizing waste generation (reuse, recycling, repurpose), improving waste disposal practices, and enhancing resource recovery to avoid GHG emissions from landfills and incineration.

Under the Paris Agreement, nations are committed to achieve net-zero emissions by mid-century to keep global warming to well below 2°C, preferably 1.5°C. Achieving these decarbonization targets requires a combination of strategies:

- Expanding renewable energy to replace fossil fuels.

- Improving energy and resource efficiency across buildings, systems, and infrastructures.

- Implementing carbon removal solutions, including biogenic carbon removal, which captures and stores carbon from organic sources such as plants, biomass and food waste.

While reducing emissions across sectors is essential, some level of residual emissions will remain unavoidable. Offsetting typically addresses these by funding external projects, which may operate outside a company’s direct operations or supply chain. Insetting, by contrast, achieves emissions reductions or removals within a company’s own value chain, meaning the climate benefits are generated internally from core business activities.

For UBQ Materials, these reductions occur directly through its waste-to-resource process, which transforms mixed municipal waste into valuable secondary raw materials. Because these carbon benefits arise within UBQ’s own processes and product lifecycle, the company can quantify reductions with higher confidence compared to many external offset projects. This insetting approach not only cuts emissions from material extraction and waste disposal but also produces durable, bio-based thermoplastic composites that displace fossil-based materials. By integrating emissions reductions into the core of its operations, UBQ advances resource conservation and supports broader climate goals.

How UBQ Materials Drives Decarbonization

UBQ Materials has developed a pioneering waste to value process that converts mixed municipal solid waste (MSW), including organic waste like banana peels, chicken bones, and food scraps, into UBQ™, a bio-based thermoplastic composite. This innovative advanced technology offers a viable alternative to conventional waste management practices such as landfilling and incineration, both of which contribute significantly to greenhouse gas emissions.

The material not only diverts mixed waste from linear climate-damaging end-of-life treatments but also fosters a circular economy by giving discarded materials a second life (secondary raw materials) in new, durable products. UBQ™ offers a sustainable, circular alternative that directly displaces oil-based plastics (virgin and recycled) in a wide range of products, reducing their environmental footprint compared to conventional plastics (∆impact) and decarbonizing their supply chain raw materials (Scope 3.1), This closes the loop, turning waste from an environmental liability into a valuable, sustainable resource for industry production.

UBQ™ as an Alternative End-of-Life Solution (from waste liability into a circular economy asset)

Instead of sending municipal solid waste to landfills or incinerators, where it contributes to greenhouse gas emissions and climate change, the UBQ™ process:

- Converts landfill or incineration-bound mixed municipal solid waste into a valuable raw material, giving waste a new life as a sustainable product composite.

- Prevents methane emissions by diverting organic material from anaerobic decomposition in landfills, where it would otherwise generate one of the most potent greenhouse gases.

- Significantly reduces GHG emissions, supporting corporate and national decarbonization targets and contributing to a more sustainable circular approach to waste management.

UBQ™ as a Materials Solution to Replace Traditional Polymers

UBQ™ is not only an alternative end-of-life solution but also serves as a sustainable, circular, low-carbon replacement for traditional, petroleum-based polymers. It:

- Reduces the net total carbon footprint of products by integrating waste-derived, low-carbon material with biogenic carbon removal (cradle to gate), helping manufacturers achieve Scope 3 emissions reductions by cutting the indirect emissions associated with raw material extraction and production, and lowering the carbon intensity of their products to support net-zero and ESG targets. This impact is driven by both low fossil and land-use change global warming potential (GWP = 0.15) and significant biogenic carbon removal (–1.17 cradle to gate), resulting in a net total of –1.02.

- Is compatible with existing manufacturing processes and equipment, including injection molding, compression molding, extrusion, rotomolding, and 3D printing.

- Works as a replacement with widely used polymers such as PP, PE, PLA, and PVC, meeting performance standards while supporting end-of-life circularity and reducing dependency on fossil-based materials.

UBQ’s Process: Low Carbon Material, Only Transformation

It is important to clarify that UBQ waste conversion process does not carbonize organic waste. Unlike high-temperature pyrolysis or gasification technologies that produce biochar, Syngas or bio-oil, coal or coke, the UBQ process converts mixed municipal solid waste into a thermoplastic bio-based composite material through a clean, low-impact process:

- Operates at a relatively low temperature of 190°C.which is far below pyrolysis or gasification temperatures that typically exceed 400–800°C. This lower temperature helps minimize energy input and thermal degradation.

- Involves no combustion, no pyrolysis, and produces no direct emissions. (e.g., no dioxins, furans, or particulate matter). The process itself uses electricity, but in cradle to gate boundaries, fossil fuel is used to transport the waste from the MRF, as a result the fossil GEP is 0.147.

- Uses zero added water into the operations and generates zero liquid effluents.

- The facility is powered entirely by 100% renewable energy from solar and wind sources (guarantees of origin).

Biogenic Removal and Climate Positivity

Biogenic carbon removal refers to capturing and storing carbon that originates from biological sources such as plants, food waste, and other organic materials. When managed properly, it cycles through the biosphere without increasing net atmospheric CO₂. Unlike fossil carbon, which is released into the atmosphere (adds new carbon to the atmosphere) from extracted oil, coal, or natural gas and adds to net global emissions and worsening climate change, biogenic carbon is part of the natural carbon cycle. However, when organic waste is decomposed in landfills, it releases carbon back into the atmosphere as methane (CH4) or CO2, contributing to climate change.

There are several processes and technologies for carbon removal, including afforestation, bioenergy with carbon capture and storage (BECCS), direct air capture, and materials-based biogenic removal pathways like UBQ’s technology, which focuses on embedding organic carbon into new long-lasting materials.

The UBQ™ process captures and locks biogenic carbon within its thermoplastic composite matrix, preventing its release and storing it in durable products used in construction, infrastructure, logistics, and consumer goods. This approach not only prevents methane emissions from organic waste decomposition but also keeps biogenic carbon out of the atmosphere for the lifespan of these products.

According to a third-party Life Cycle Assessment (LCA) conducted by ERM:

- Every kilogram of UBQ™ produced in the Netherlands (NL), removes 1.17 kg CO2eq of biogenic carbon, with a production (fossil and land-use change GWP) footprint of only 0.15 kg CO2eq per kilogram UBQ™ tablets.

- This results in a net cradle-to-gate carbon footprint of (-1.02) kg CO2eq per kilogram of UBQ™ produced in NL, making it a climate-positive material that supports waste decarbonization and emissions reduction efforts globally.

Supporting a Circular, Low-Carbon Economy

UBQ™ supports the transition towards a circular and low-carbon economy by converting mixed municipal solid waste, including organic fractions, that would otherwise contribute to methane emissions in landfills, into a valuable, climate-positive thermoplastic composite. This process turns waste from an environmental burden into a valuable secondary raw material that can replace or enhance traditional fossil-based polymers, reducing reliance on virgin raw materials and supporting sustainable development goals. By extending the life cycle of resources and keeping materials in continuous productive use, UBQ™ supports the circular economy principles promoted by the European Parliament’s objectives to reduce waste generation, conserve natural resources, limit biodiversity loss, cut greenhouse gas emissions, and mitigate the environmental impacts of extraction and disposal.

For companies, integrating UBQ™ into their products contributes to scope 3 emissions reductions, helping achieve net-zero targets by lowering the overall carbon footprint of manufactured goods. Importantly, UBQ™ is compatible with existing manufacturing processes, including injection molding, compression molding, extrusion, rotomolding, and 3D printing, enabling seamless adoption across industries without compromising performance standards or production efficiency.

Conclusion

UBQ Materials goes beyond recycling, positioning itself as a key solution in waste, decarbonization, climate positivity, and circular economy leadership. As industries, governments, and communities worldwide accelerate efforts to reduce greenhouse gas (GHG) emissions, meet ambitious net-zero targets, and decrease reliance on virgin raw materials, UBQ™ offers a proven, scalable pathway with measurable climate impact benefits and supply chain compatibility.

Join us in transforming mixed landfill and incineration-bound solid municipal waste into a resource for a sustainable future. Industry leaders, businesses, customers, and policymakers can integrate UBQ™ to achieve decarbonization targets and build a world where waste is no longer wasted but becomes a cornerstone of circularity and low-carbon economic growth.