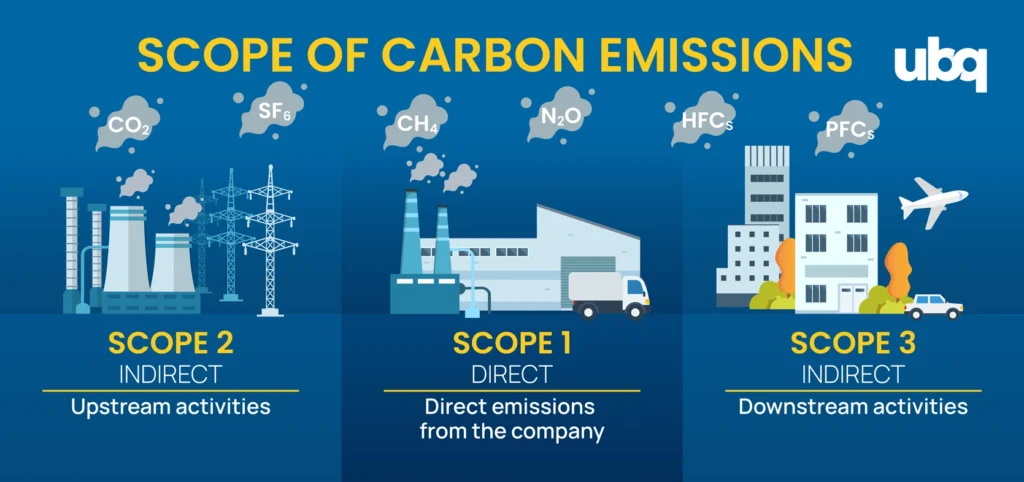

Achieving meaningful climate action requires understanding and addressing greenhouse gas emissions across the value chain. These emissions are categorized into three scopes, as defined by the Greenhouse Gas Protocol:

- Scope 1: Direct emissions from owned or controlled sources.

- Scope 2: Indirect emissions from purchased electricity, steam, heating, and cooling.

- Scope 3: All other indirect emissions occurring across an organization’s value chain.

Reducing these emissions is critical in mitigating climate change. While Scope 1 and 2 emissions are tied to a company’s direct operations and are influenced by its internal efforts, Scope 3 emissions stem from the broader supply chain. This category represents a significant opportunity for improvement, as it encompasses upstream and downstream activities where meaningful change can drive substantial impact.

At UBQ Materials, our patented technology transforms mixed household waste, including organics and hard-to-recycle materials, into a climate-positive thermoplastic composite, UBQ™. By integrating UBQ™ into durable and semi-durable products across both upstream and downstream supply chain activities, companies can significantly reduce their environmental impact. It offers a powerful solution to reduce and avoid greenhouse gas emissions at the supply chain level.

Scope 1 Emissions: Direct Emissions from Operations

Scope 1 emissions originate from company-owned or controlled sources, including fuel combustion in facilities, industrial processes, and vehicle fleets owned or controlled by the company. These emissions contribute directly to climate change and require proactive reduction strategies.

Sources of Scope 1 Emissions:

- Stationary combustion: Emissions from burning fuels for heating, boilers, and manufacturing.

- Mobile combustion: Fuel used in company-owned vehicles.

- Fugitive emissions: Leaks from refrigeration, air conditioning, or industrial gases.

- Process emissions: Emissions from chemical and industrial manufacturing.

Scope 2 Emissions: Indirect Emissions from Energy Consumption

Scope 2 emissions stem from the generation of purchased electricity, steam, heating, and cooling used by an organization. While these emissions do not come directly from company operations, they are influenced by energy sourcing decisions.

Sources of Scope 2 Emissions:

- Electricity consumption: Carbon intensity depends on the energy mix of the provider.

- Heating and cooling systems: Emissions from purchased steam or district heating.

Scope 3 Emissions: Indirect Emissions Across the Value Chain

Scope 3 emissions encompass a company’s entire value chain, from supplier emissions to product end-of-life (EOL) disposal. These emissions are often the most challenging to measure and mitigate, yet they often represent a significant portion of an organization’s carbon footprint.

Scope 3 includes all other indirect emissions that occur in the value chain of the organization, from both upstream and downstream activities within 15 categories. As an example, a manufacturing company would need to account for its equipment, raw materials, transportation to and from the factory, and use and ultimate disposal of its products, among other things.

Sources of Scope 3 Emissions:

- Purchased goods and services: Carbon footprint of raw materials.

- Transportation and distribution: Emissions from shipping and logistics.

- Waste disposal: Landfilling and incineration of waste produced by the company.

- EOL emissions: Emissions from product disposal.

Scope 3 Emissions: Upstream vs. Downstream & UBQ’s Role in Sustainability

When businesses calculate their carbon footprint, Scope 3 emissions (indirect emissions occurring outside direct company operations) are often the hardest to calculate and reduce. These emissions are divided into two categories:

- Upstream Scope 3 Emissions: These emissions are generated before a product is manufactured. This includes the extraction of raw materials, supplier energy use, employee commuting, leased assets, and logistics.

- Downstream Scope 3 Emissions: These occur after a product has left a company’s hands and include emissions from product transportation, use, and disposal.

UBQ’s Greenhouse Gas Emissions

UBQ Materials’ Scope 1 and 2 emissions are lower than for many material manufacturers thanks to the company’s energy-efficient production process and high use of renewable energy. UBQ is in the process of conducting a Scope 3 emissions inventory.

In UBQ’s role as a supplier, we can contribute to our partners’ goals to reduce their Scope 3 emissions. UBQ™ material is a low-carbon product that can replace conventional materials with higher carbon footprints. UBQ™ also offers additional climate benefits that do not fit into Scopes 1, 2, and 3, on top of broader sustainability assets such as circularity and recycled content.

Life Cycle Assessment (LCA) Results for UBQ Tablets Produced at Bergen op Zoom

UBQ’s net cradle-to-gate carbon footprint is -1.02 kg CO2eq/kg UBQ tablets. The total carbon footprint calculation is composed of two main parts:

- Production Process Emissions (cradle to gate): The emissions associated with the production of a product from its initial raw material extraction (“cradle”) up to the point it is packed and ready at the factory gate to be transported to the customer. This includes emissions from extracting all raw materials needed for production, emissions from transporting the raw materials to the factory, and the emissions associated with the manufacturing process itself, including energy use and industrial processes.

UBQ efficient production and use of renewable energy generate only 0.15 kg CO2eq/kg UBQ tablets—as little as 1/20 of the greenhouse gas emissions of virgin polymer production—and uses minimal land for production and sourcing of raw materials.

- Biogenic carbon removal: Biogenic carbon removal refers to the capture of carbon dioxide (CO₂) that is derived from biological sources (such as food, wood, paper, and grass trimmings). Plants absorb CO₂ from the atmosphere and convert it into biomass through photosynthesis. This CO₂ is temporarily stored in plant tissues as is part of the natural carbon cycle. By converting this biomass into a useful material, UBQ removes nearly 1.2 kg CO2eq of biogenic carbon per kg of UBQ tablets produced.

This carbon will eventually cycle back to the atmosphere due to degradation processes at the product’s EOL and can be prevented by:

- Extending its longevity: designing products with a focus on durability and extended lifespan.

- Promoting a circular business model: making sure that products reenter the lifecycle process through recycling, repurposing, or reusing, including take back programs.

While carbon is a key metric in sustainability, it’s only one part of the picture. A comprehensive environmental assessment requires a broader range of impact categories. UBQ Material’s LCA looks at the environmental impacts on air quality, land use, resource utilization, built infrastructure, and oceans. Download the LCA Report Executive Summary here.

By replacing conventional plastics with UBQ™, businesses can take measurable steps towards achieving the sustainability targets, removing and avoiding greenhouse gas emissions, and supporting a circular economy.

UBQ™’s Benefits

UBQ™ is a climate-positive, thermoplastic composite made from household waste, including all organics and hard-to-recycle materials. It enables companies to create more sustainable products without extracting new resources from the planet.

Its key benefits include:

- Reduces reliance on petroleum-based plastics and other extracted materials.

- Removes carbon from the atmosphere through biogenic carbon storage in the organic material.

- Avoids methane and carbon emissions generated by the decomposition of organic waste in landfills.

- Recyclable at EOL, promoting resource conservation and advancing the circular economy.

- Even a small amount of UBQ™ in formulations helps you advance toward emissions reduction goals.

When UBQ™ is incorporated into a product formulation, it functions as a raw material. Thanks to its low carbon footprint, it can help reduce a company’s downstream Scope 3 emissions. Additionally, UBQ™ can also help lower upstream Scope 3 emissions when used in products related to a company’s logistics and transportation, such as pallets, bottle crates, and transport boxes, providing sustainable impact across the entire value chain.